Contact Us

Hotline

+86 10 62149667

VINIPET® B6B-23 Wiggle Wire

★ Two thick ends, easy to install with high efficiency;

★ Special spring steel, better character to fix the film;

★ Coating with project plastic powder, better anti-aging character;

★ 8 steps of procedures, high-quality standard.

1. Product features

(1) Save the cost

(a) The coating wiggle wire in the market will be broken due to poor quality coating materials, so it can not be used repeatedly;

(b) Vinipet wiggle wire uses spring steel with anti-aging resin for many years. The wire can be used 6- 8 years repeatedly. It may really save much cost.

(2) Safe

(a) The wiggle wire cost is less 1% of the total greenhouse cost. But the 1% wire ensure 100% safety of the greenhouse;

(b) The Vinipet series wiggle wire adopts engineering plastic powder with better anti-aging character. The wiggle wire can withstand wind of grade 14 and fix the film more strong;

(c) The wiggle wire in the market is sharp at two ends, it is easy to cut the film. The ends of Vinipet wiggle wire is more thick and round, it is easy to install and harmless to the film in installation.

2. Development History

In 2000, VINIPET® Wiggle Wire was invented and sold in Japan;

In 2003, VINIPET® Wiggle Wire was indicated as government procurement product of Shanghai;

In 2011, VINIPET® Wiggle Wire sales had been over 26 million pieces in China;

In 2015, two ends thick design brought innovation to the wiggle wire, and new VINIPET® B6 Wiggle Wire went on the market;

In 2016, VINIPET® B5B White Wiggle Wire went on the market and received good reviews from users;

In 2017, as the only participant Beijing Fenglong laid down the Wiggle wire standard for greenhouse JB/T13080-2017.

3. Product Features and Case

(1) VINIPET® Wiggle Wire features

(a) Quality: VINIPET® Wiggle Wire was designed forJapanby Japanese standard, it has 8 steps of procedures with special spring steel wire. It uses anti-aging resin, and is made in strict management system; it has been exported to Japan for 20 continuous years;

(b) R&D: Headed by the general manager, the Japanese and Chinese engineers formed a team along with university researchers, the team handled problems in the productions.

(2) Cooperation

Our company maintains a long-term strategic relationship with Japan's Mitsui Chemicals, Kyowa Chemical Industry, C.I. Takiron, RIKEVITA, and the Institute of Chemistry Chinese Academy of Sciences and Chinese Academy of Agricultural Sciences.

(3) Case

Thru years of marketing, Our company products have been used in many big growing bases within China and in many other countries, including Japan Toto, Israel Netafim, France Richel and many big plant bases in China.

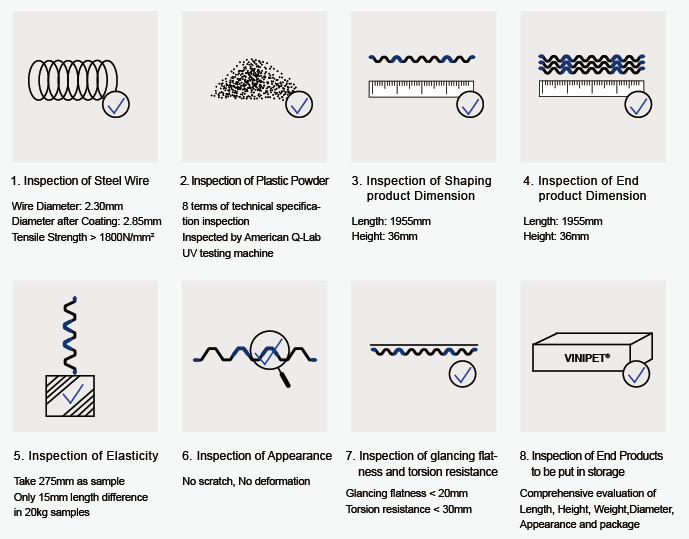

4. 8 Steps of Inspection Procedures

5. Test inspection comparisons

(1) 14 grade wind simulation test

The load for 14-grade wind is 133 kgs per sqm, to stand 14-grade wind, the wiggle wire should stand 260kgs or above per sqm. According to the test, 2 VINIPET® Wiggle Wires stand the load of 580 kgs, and each Wiggle Wire is sharing 290 kgs, which meets the 260 kgs requirement.

(2) Anti-aging test

To have 6 years of good performance for B6 wiggle wire, our company introduces Q-Lab machine to check the VINIPET® B6 Wiggle Wire regularly.

(3) Wiggle wire straightness test

Uninstall the vinipet wiggle and the other brand of wiggle wire from the channel and compare them as in the picture.

Add:Bldg. 5, CAAS, Beijing, China

Tel :+86 10 62149667

Fax:+86 10 82108614

Email: market@bflc.cn

P.C: 100081